P2 SMPs

| apl. Prof. Dr. Fathollah Varnik | Dr.-Ing. Rasa Kazakeviciute-Makovska |

|

|

| fathollah.varnik@rub.de | kama@lkm.rub.de |

| Prof. Dr.-Ing. Günther Eggeler | Prof. Dr.-Ing. habil. Holger Steeb |

|

|

| gunther.eggeler@rub.de | holger.steeb@mechbau.uni-stuttgart.de |

Shape memory polymers (SMPs), including shape memory polymer nanocomposites (SMPNCs), belong to a class of smart materials with potential applications ranging from biomedicine and nano-engineering to space technology. Compared to shape memory alloys and ceramics, SMPs have various advantages such as low density, easy processing, high fixture strain and high strain-recovery ability, wide shape transition temperature, biocompatibility, and even relatively low cost.

The majority of earlier studies on SMPs has been primarily focused on synthesis and characterization of these materials, tuning and optimization of their functional (shape memory) properties as well as their biocompatibility and biodegradability with a view of biomedical applications. The potential engineering applications of SMPs have received relatively less attention. Such applications require SMPs having enhanced mechanical and thermal properties, high recovery stresses, and a good reproducibility of shape fixity and shape recovery in multiple programming/shape recovery cycles, that is, SMPs which are both materially stable and resistant to the mechanical, thermal, and functional fatigue.

To assist an efficient design and use of SMP-based elements and devices in engineering and other fields, it is necessary to develop:

► efficient experimental procedures to characterize mechanical, thermal, and functional properties of these materials,

► physically-sound constitutive models capturing the key features of the behavior of SMPs subjected to arbitrary strain, stress, and temperature histories,

► reliable methods to evaluate the constitutive models and to validate models prediction with experimental results,

► methodology to determine response functions in thermo-mechanical models and to calibrate material parameters from measurable data, and

► computational algorithms for the analysis of particular problems.

The characterization and modeling of SMPs is a difficult task due to:

► different types (amorphous, semicrystalline, etc., with chemically or physically crosslinked network structures),

► various functional properties (dual and multiple shape memory effects, one- and two-way shape memory effects, temperature memory effect, etc.),

► different kinds of stimuli (temperature, electrical current/voltage, magnetic field, light, pH-change/solvent/water/moisture, etc.) as well as

► different physical mechanisms responsible for a macroscopic behavior.

Latest Research Results

Molecular dynamics simulations of a shape memory polymer.

The box to the left shows a single molecule out of 1600 chains (each co-polymer chain has 300 monomers)

Continuum modelling of shape memory polymer with a complex geometry showing a polymer-based stent with shape memory property

Experimental characterization of SMPs requires the determination of their mechanical (elastic and rheological) and thermal properties as well as the quantification of the functional (shape-memory) behavior. The functional properties are quantified in multi-step cyclic thermomechanical tests. Each cycle involves the programming of a sample and the recovery of its permanent shape. Depending on the instrumental setup used in experiments, these tests can be performed in strain- or stress-controlled modes such as uniaxial tension, (simple/pure) shearing or bending of suitable samples. In addition, different functional properties require slightly different shape memory characterization procedures. These differing experimental methods and testing protocols result in a great variety of data making the evaluation of the shape memory performance under different thermo-temporal conditions somewhat difficult.

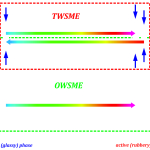

Thermo-responsive shape memory polymers: One-Way Shape Memory Effect (OWSME) and Two-Way Shape Memory Effect (TWSME)

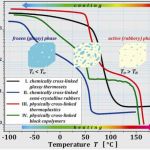

Four main categories of SMPs (according to Liu, Qin and Mather [2007]) quantified in DMTA temperature sweep test

Due to a large variety of chemical compositions, triggering mechanisms, and thermomechanical responses of SMPs, their mathematical modeling is intrinsically difficult. The difficulties mainly arise from the complexity of physical mechanisms involving interplay among thermodynamics, viscoelasticity, heat transfer, chain dynamics, phase transition and other factors.

This project is concerned with continuum-mechanics based modeling of thermo-responsive SMPs, including SMPNCs, with both the conventional methods of actuation, such as a direct heating, as well as the inductive heating. For such models to be applicable in various engineering fields, their formulations must take into account the general thermo-temporal effects (e.g. very low frequency response and long time behavior) as well as the chemo-rheological aging of these smart materials in aggressive chemical environments.

Project related publications

R. Kazakevičiūtė-Makovska, M. Heuchel, K. Kratz, H. Steeb, Universal relations in linear thermoelastic theories of thermally-responsive shape memory polymers,

International Journal of Engineering Science, 82, 140-158, 2014.

R. Kazakevičiūtė-Makovska, A. Özlem Özarmut, H. Steeb, Characterization of shape memory polymer EstaneTM by means of dynamic mechanical thermal analysis technique,

Smart Materials Research, 2014, article ID 250258, 9 pages.

S. Mogharebi, R. Kazakevičiūtė-Makovska, H. Steeb, G. Eggeler, K. Neuking, On the cyclic material stability of shape memory polymer Estane, Materialwissenschaft und Werkstofftechnik, 44(6), 521-526, 2013.

R. Kazakevičiūtė-Makovska, S. Mogharebi, H. Steeb, G. Eggeler, K. Neuking, A critical assessment of experimental methods for determining the dynamic mechanical characteristics of shape memory polymers,

Advanced Engineering Materials, 15(8), 732-739, 2013.

R. Kazakevičiūtė-Makovska, H. Steeb, A.Ö. Aydın, On the evolution law for the frozen volume fraction in linear theories of shape memory polymers,

Archive of Applied Mechanics, 82(8), 1103-1115, 2012.

R. Kazakevičiūtė-Makovska, H. Steeb, On recoverable strain and stress relationships for shape memory polymer nanocomposites,

KGK: Kautschuk Gummi Kunststoffe, 6, 24-28, 2011.

A. Marquardt, S. Mogharebi, K. Neuking, F. Varnik, G. Eggeler, Diffusion of small molecules in a shape memory polymer,

Journal of Materials Science, 2016, 51, 9792–9804.

E. Ghobadi, R. Sivanesapillai, J. Musialak, H. Steeb, Modeling based characterization of thermorheological properties of polyurethane ESTANE,

International Journal of Polymer Science, (2016), Article ID 7514974.

E. Ghobadi, H. Steeb, R. Sivanesapillai, On the modeling of thermo-viscoelastic behavior of shape-memory Polymers,

Constitutive Models for Rubber VIII.

E. Ghobadi, A. Marquardt, E. Mahmoudinezhad, K. Neuking, F. Varnik, G. Eggeler, H. Steeb, Physical aging improves the functional properties of polyether urethane ESTANE,

Submitted for publication to J. Polymer Testing (2017).

E. Mahmoudinezhad, A. Marquardt, G. Eggeler, F. Varnik, Molecular dynamics simulations of entangled polymers:The effect of small molecules on the glass transition temperature,

Submitted for publication to Procedia Computer Science (2017).

E. Mahmoudinezhad, A. Marquardt, G. Eggeler, F. Varnik, Non-monotonic effect of small molecules on the glass transition temperature of polymers,

Submitted for publication to Macromolecules (2017).

Project related oral presentations

E. Mahmoudinezahd, F. Varnik, et al., DPG – Spring Meeting, March 2017 – Effect of small molecules on the glass transition in entangled and non-entangled polymers

F. Varnik et al. , 8th International Conference on Multiscale Materials Modelling Dijon, France, October 2016 – Chemo-mechanical coupling in shape memory polymers: Theory versus experiment

E. Mahmoudinezahd, F. Varnik, Materials Science and engineering Congress, Darmstadt, September 2016, Germany – Molecular dynamics simulation studies of polymers in the presence of small molecules

E. Ghobadi, H. Steep, Gesellschaft für Angewandte Mathematik und Mechanik e.V. (GAMM) 2016 – Fractional calculus for modeling of viscoelastic properties of functional polymers.